Mechanical Engineering

About of the Department :

The Department of Mechanical Engineering was introduced in the year of Independence 1947. Since then our department has produced four generations of people who have served in their highest capacity in and around the country. The Department has well equipped laboratories with vintage equipments/machineries as well as modern ones, which are being utilized by the students for project work as well as for developing IRG. .

vision

To develop the department of Mechanical Engineering as the centre of excellence while producing quality mechanical engineers who can contribute efficiently to the technological development.

Mission

• Imparting quality education to make the mechanical engineers globally competitive.

• To develop state of art facility related to mechanical engineering.

• To provide personality development skills to the students for exploring their leadership quality.

PROGRAMME EDUCATIONAL OBJECTIVES (PEOs):

PEO-1: To obtain fundamental knowledge about various fields of mechanical engineering.

PEO-2: To cater employable skills for employment in public or private sector.

PEO-3: To opt for higher studies in order to pursue a career of choice or for more employment benefit.

PEO-4: To obtain entrepreneurial skill for being self-employed as well as promoting jobs for others

PROGRAMME OBJECTIVES:

PO-1 Basic knowledge-

An ability to apply knowledge of basic mathematics and science to solve the engineering problems

PO-2 Discipline knowledge:

An ability to apply mechanical discipline - specific knowledge to solve core and/or applied engineering problems

PO-3 Problem analysis:

Analyze well defined engineering problem using codified standard method.

PO-4 Design/ development of solutions:

Design solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs

PO-5 Engineering tools and experiments:

An ability to apply modern engineering tools and appropriate technical skills to conduct test and measurements

PO-6 Engineering practices

Apply appropriate technology in context of society, environment and sustainability

PO-7 Project Management & Communication:

Apply management principles for execution of project work in a team with proper communication

PO-8 Lifelong learning:

Apply to learn and analyze new concepts and technology to satisfy the changing needs

PROGRAMME SPECIFIC OUTCOMES (PSOs):

PSO-1: Apply the acquired knowledge in design, thermal, manufacturing and interdisciplinary areas for solving industry and socially relevant problems.

PSO-2: To enhance the abilities of students by imparting knowledge in emerging technologies to make them confident mechanical Engineers.

PSO-3: Provide socially responsible ,eco –friendly broad base solution to mechanical Engineering related problems adopting professional ethics.

STAFF PROFILE

|

Sl. No |

Faculty Name |

Designation |

D.O.J |

Qualification |

NOA |

Photo |

|

1 |

SUNITA SAMAL |

HOD |

03.12.2013 |

Mtech in thermal Engg. |

Regular |

|

|

2 |

SUNITA NAYAK |

LECTURER |

12.11.2015 |

M.tech in manufacturing engg. |

Regular |

|

|

3 |

SUSHREE PRIYADARSHINI

|

LECTURER |

13.11.2015 |

M.tech in heat power engg |

Regular |

|

|

4 |

PRIYADARSHINI MALLICK |

LECTURER |

21.01.2019 |

B.Tech |

Regular |

|

|

5 |

RUTUPARNA SAHU |

LECTURER |

|

|

Regular |

|

|

6 |

PRABIR KUMAR SWAIN |

LECTURER |

22.01.2019 |

B.Tech |

Regular |

|

|

7 |

BABITA PANDA |

LAB-Assistant |

|

|

Regular |

|

|

8 |

BIDYUT RANJAN ROUT |

PTGF |

19.09.22 |

M.Tech in production |

Guest Lecturer |

|

|

9 |

BIBEKANANDA PRATIHARI |

PTGF |

|

|

Guest Lecturer |

|

|

10 |

S.P.B.B BHATTA |

PTGF |

15.7.2017 |

|

Guest Lecturer |

|

|

11 |

CHIRANJEEVI PATTNAIK |

PTGF |

15.12.2020 |

B.Tech |

Guest Lecturer |

|

|

12 |

PRASANT KUMAR PADHI |

PTGF |

26.10. 2022 |

M.Tech heat power engg. |

Guest Lecturer |

|

|

13 |

ACHYUT KUMAR PATRA |

PTGF |

08.12.2021 |

B.Tech |

Guest Lecturer |

|

|

14 |

NARESH KUMAR PRADHAN |

PTGF |

10.11.2021 |

B.Tech |

Guest Lecturer |

|

| SL.NO. | NAME OF THE STAFF | DESIGNATION | QUALIFICATION | EXPERIENCE | MOBILE NO. | MAIL ID | RECENT PHOTOGRAPH |

|---|---|---|---|---|---|---|---|

|

1 |

Mr. H.K. BARIK |

Workshop Suptd (I/C) |

B.Sc. ENGG. (MECH) |

33 years |

7978081080 |

barik.hemanta54@gmail.com |

|

|

2 |

Mr. P.K. SWAIN |

Lecturer |

B. TECH. |

2 years |

9776625055 |

prabirswain.179@gmail.com |

|

|

3 |

Mr. BISWANATH PRADHAN |

Guest Faculty |

B. TECH |

5 years |

7978556058 |

mantu.mantu8@gmail.com |

|

|

4 |

Mr. SUSHANTA KUMAR PRADHAN |

Sr Instructor |

ITI |

30 Years |

8895655711 |

||

|

5 |

Mr. Madhusudan Parida |

Sr Instructor |

ITI |

32 Years |

9937458498 |

madhusudanlic67@gmail.com |

|

|

6 |

Hrudananda Patra |

Lab assistant |

B.Tech |

7 Years |

9853327782 |

hrudanandapatra@gmail.com |

|

|

7 |

Mr. Amitav Das |

Guest Instructor |

ITI |

15 Years |

6372155758 |

||

|

8 |

Mr.Pranab Kishore Jena |

Guest Instructor |

iti |

4 Years |

7873839418 |

Pranabjena1994@gmail.com |

|

|

9 |

mr.aswini parida |

Guest Instructor |

iti |

3 Years |

7657002128 |

aswiniparida1063@gmail.com |

|

|

10 |

mr.sanjaya kumar barik |

Guest Instructor |

diploma |

4 Years |

7789040328 |

kumarlipu93@gmail.com |

|

|

11 |

mr.ramesh chandra mallick |

class4 staff |

|

|

7684981657 |

||

|

12 |

mr.ram prasad singh |

class4 staff |

|

|

6371132671 |

LABORATORY WITH PHOTOGRAPH:

FLUID MECHANICS & HYDRAULIC MACHINES LAB

• Pelton wheel turbine

• Francis turbine

• Centrifugal pump

• Hydraulic bench

• Bernoulli’s apparatus test rig

HEAT POWER LAB

• Single cylinder two stroke petrol engine

• Flash point & fire point

• Four stroke single cylinder diesel engine

• Refrigeration tutor

• Multi cylinder four stroke engine

STRENGTH OF MATERIAL LAB

• Torsion testing machine

• Impact testing machine

• Universal testing machine

• Fatigue testing machine

• Single purchase winch crab

• Compound screw jack

• Worm & worm wheel

• Hardness testing machine

WORKSHOP

• Lathe machine

• Grinding machine

• Power hacksaw

CAD / CAM LAB

• Autocad, Solid Work

CNC MILLING & TURNING

| SL.NO. | Name of the Experiment | PHOTOGRAPH |

|---|---|---|

|

1 |

Study of pressure measuring devices (manometer, Bourdon tube pressure gauge) |

|

|

2 |

Verification of Bernoulli’s theorem |

|

|

3 |

Determination of Cd from venturimeter. |

|

|

4 |

Determination of Cc, Cv, Cd from orifice meter |

|

|

5 |

Determine of Darcy’s coefficient from flow through pipe |

|

|

6 |

Performance test on Pelton, Francis & Kaplan turbine and Centrifugal Pump to find out the efficiency |

|

|

7 |

Direct operation of hydraulic motor |

|

|

8 |

Experiment on hydraulic trainer |

|

|

9 |

Speed control double acting hydraulic cylinder using metering in & metering out circuits |

| SL.NO. | Name of the Experiment | PHOTOGRAPH |

|---|---|---|

|

1 |

Determination of centrifugal force of a governor |

|

|

2 |

Study & demonstration of Static balancing apparatus, Journal bearing apparatus, Cam and followers and Epicyclic gear train. |

|

|

3 |

Determination of the thickness of ground M.S flat to an accuracy of 0.02mm using Vernier Caliper. |

|

|

4 |

Determination of diameter of a cylindrical component to an accuracy of 0.01mm using micrometer |

|

|

5 |

Determine the heights of gauge blocks or parallel bars to accuracy of 0.02mm using Vernier height gauge. |

|

|

6 |

Determine the thickness of ground MS plates using slip gauges. |

|

|

7 |

Determination of angle of Machined surfaces of components using sin bar with slip gauges |

| SL.NO. | Name of the Experiment | PHOTOGRAPH |

|---|---|---|

|

1 |

Fitting practices: Preparation of caliper, try square, hammer (square & Hexagonal face) |

|

|

2 |

Blacksmith practice: Preparation of door ring with hook, hexagonal headed bolt, octagonal flat chisel |

|

|

3 |

Carpentry Practice: Preparation of single dove tail joint and Cutting of slot, botch, mortise and Tenon Joint |

|

|

4 |

Welding Practice: Lap & Butt Joint using Arc Welding & Gas Welding |

|

|

5 |

Various machining operations like step turning, facing, grooving, taper turning, thread cutting in Lathe machine |

|

|

6 |

Production of holes by drilling machine and enlarging by boring tool |

|

|

7 |

Generation of V-groves & flat surface by using Shaper machine |

|

|

8 |

Production of spur gears by Milling machine |

|

|

9 |

Practice of all turning operations in CNC Lathe machine |

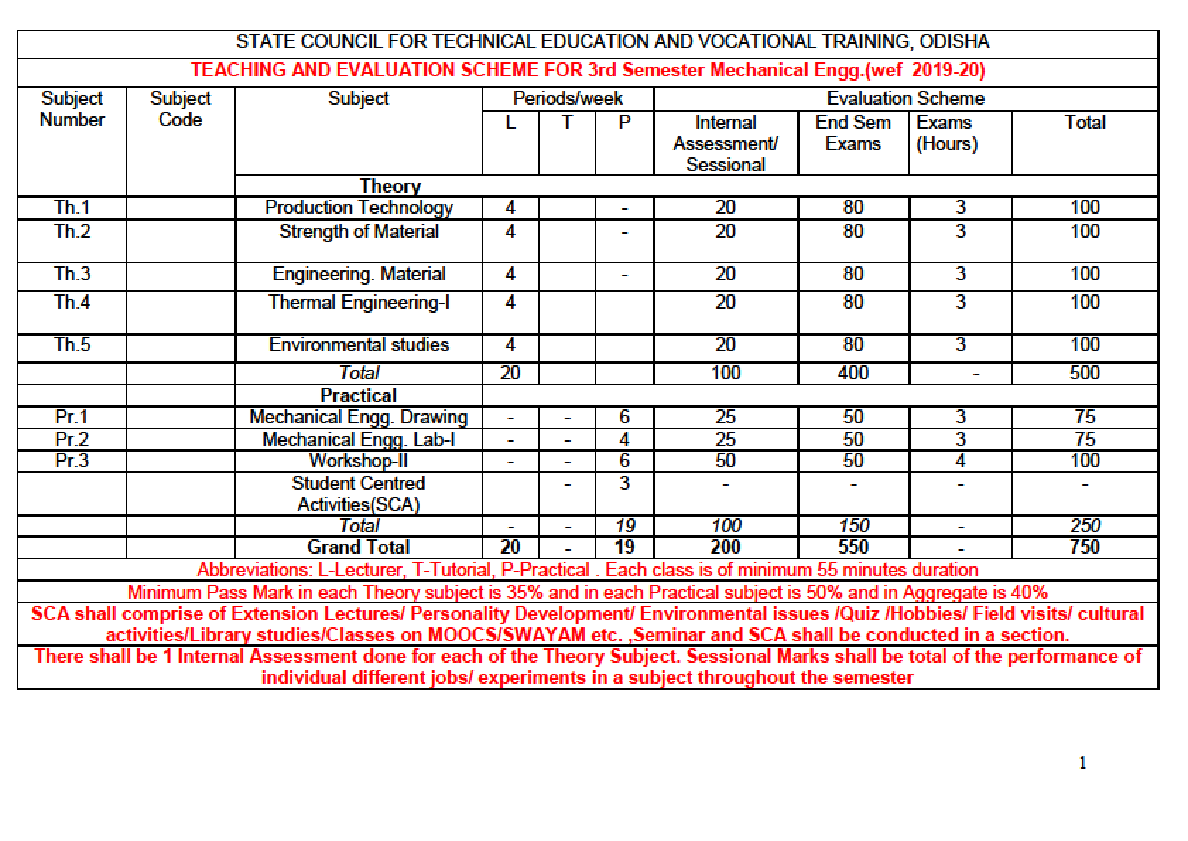

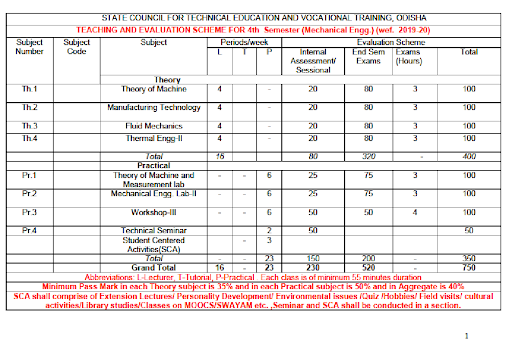

| SL.NO. | Name of the Semester | Attachment to be downloaded |

|---|---|---|

| 1 | 3rd semester |  |

| 2 | 4th semester |

|

| 3 | 5th semester |

|

| 4 | 6th semester |

>

|

| SL.NO. | Name of the subject | Attachment to be downloaded |

|---|---|---|

|

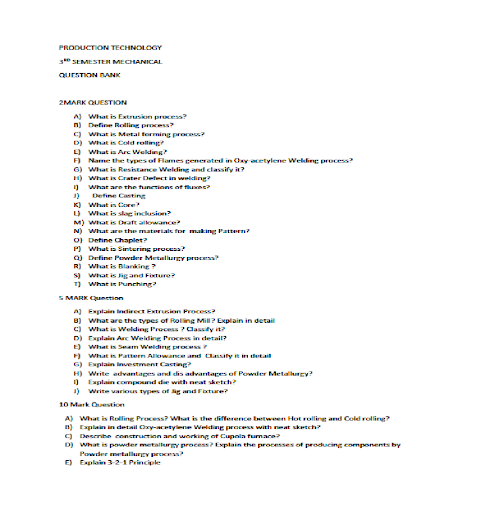

1 |

PRODUCTION TECHNOLOGY |

|

|

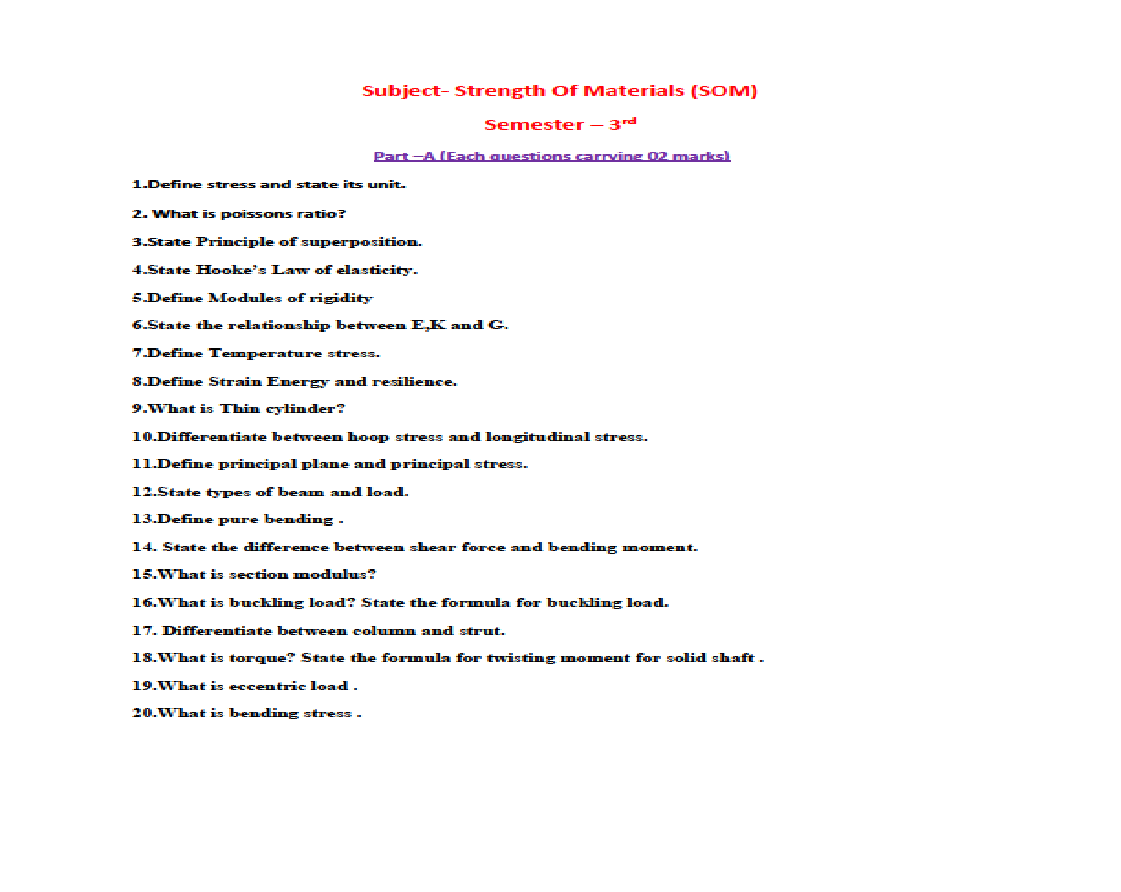

2 |

STRENGTH OF MATERIAL |

|

|

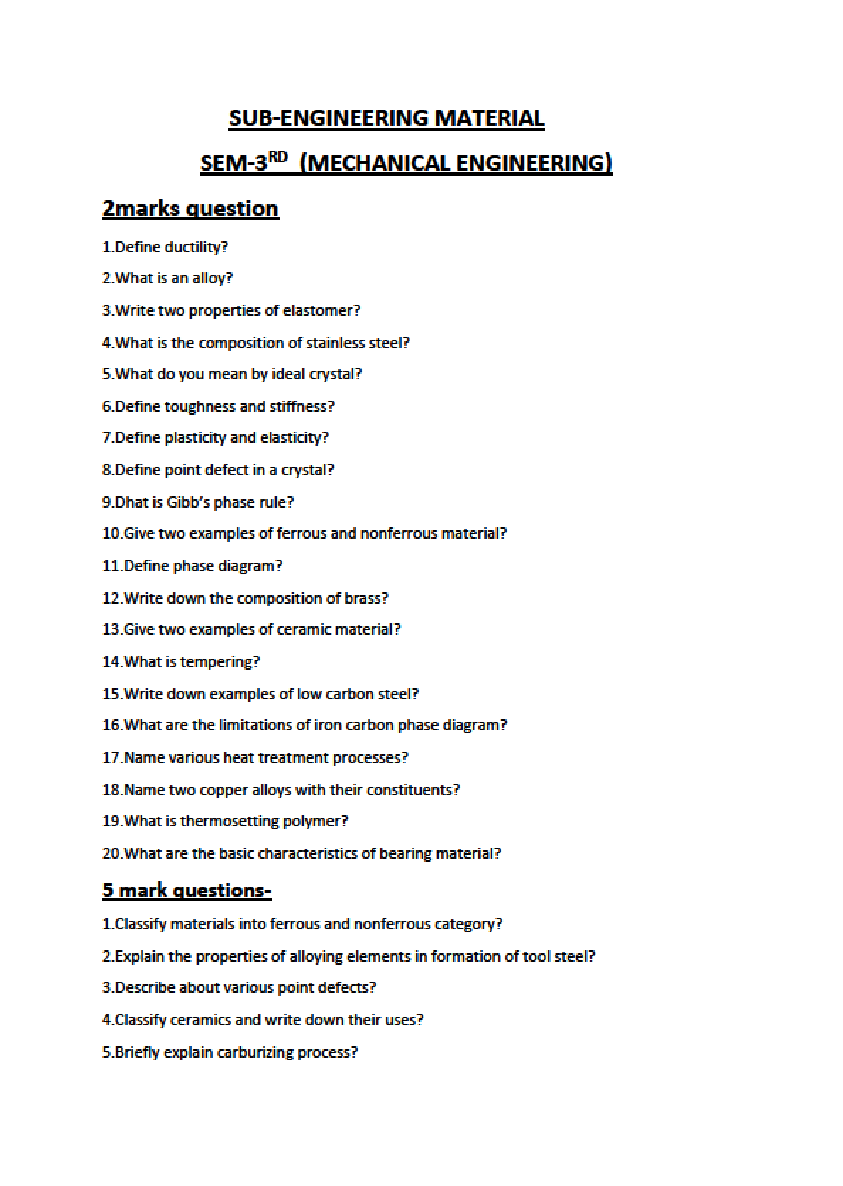

3 |

ENGINEERING MATERIAL |

|

|

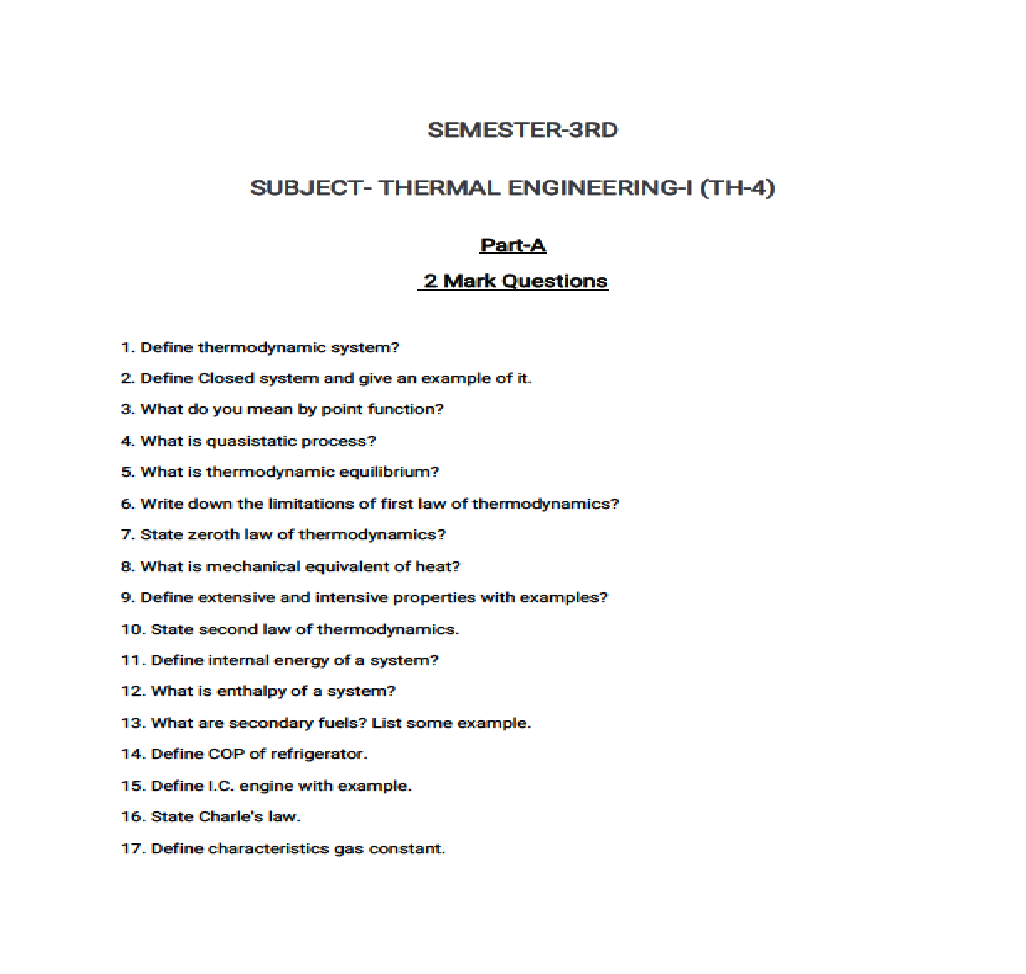

4 |

THERMAL ENGINEERING |

|

|

5 |

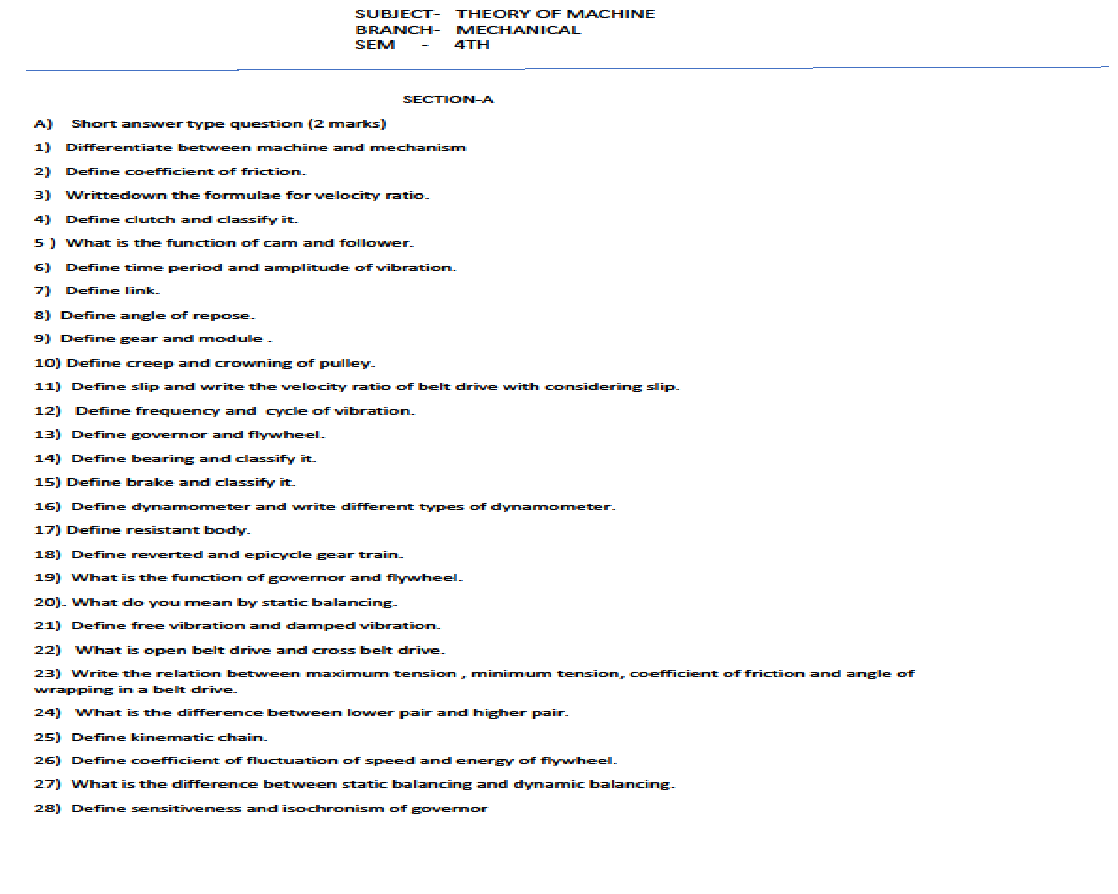

THEORY OF MACHINE |

|

|

6 |

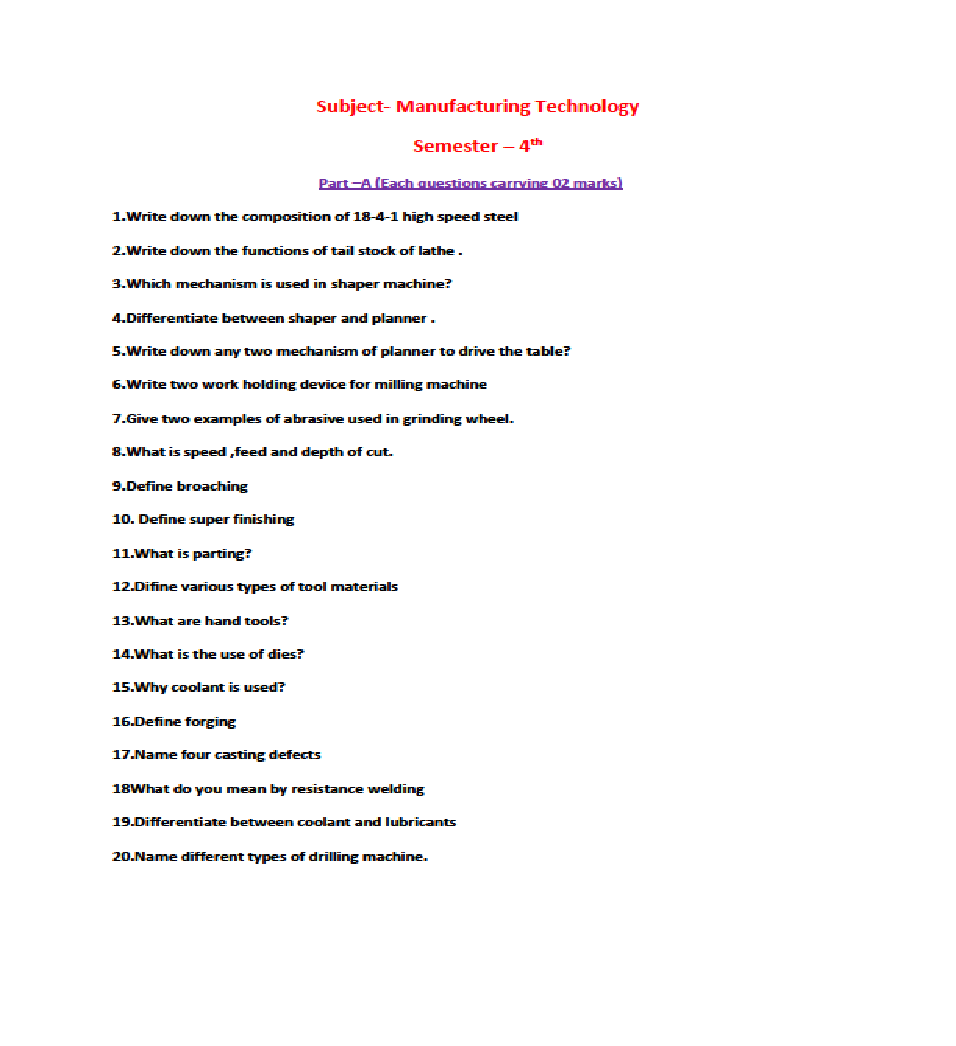

MANUFACTURING TECHNOLOGY |

|

|

7 |

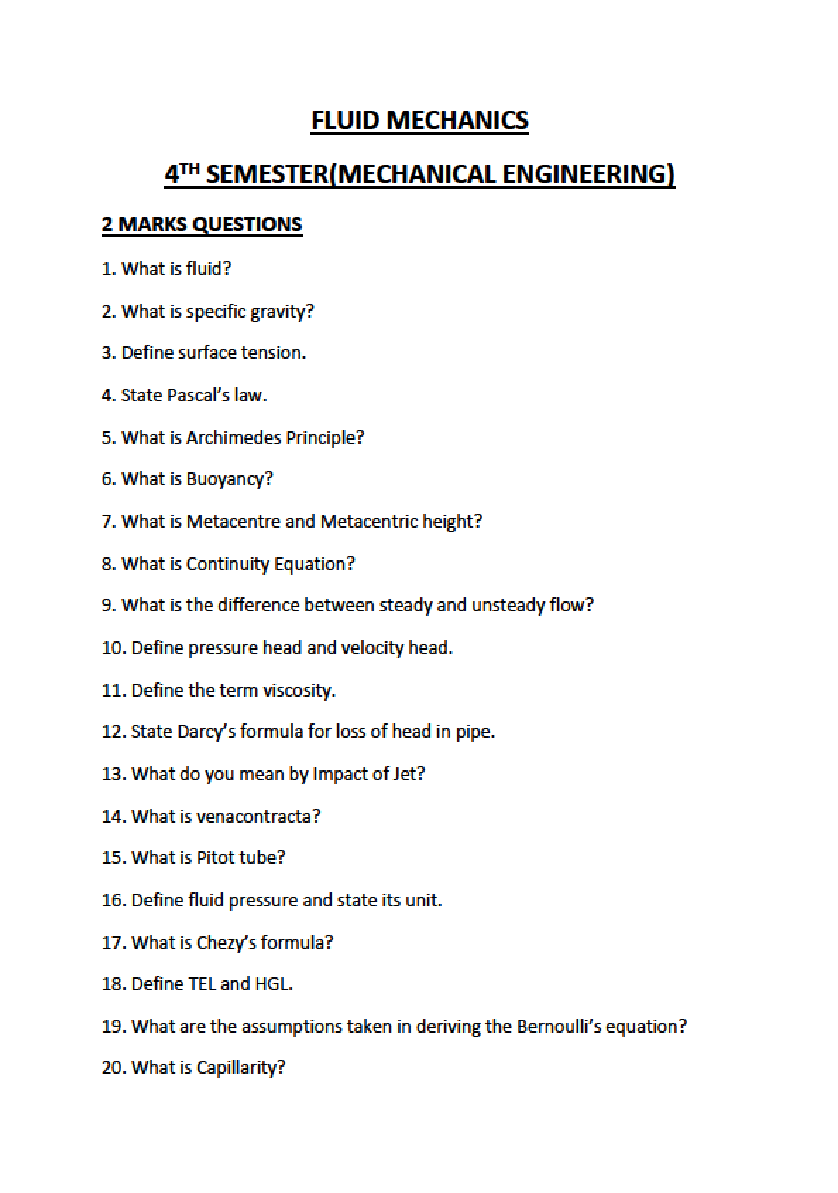

FLUID MECHANICS |

|

|

8 |

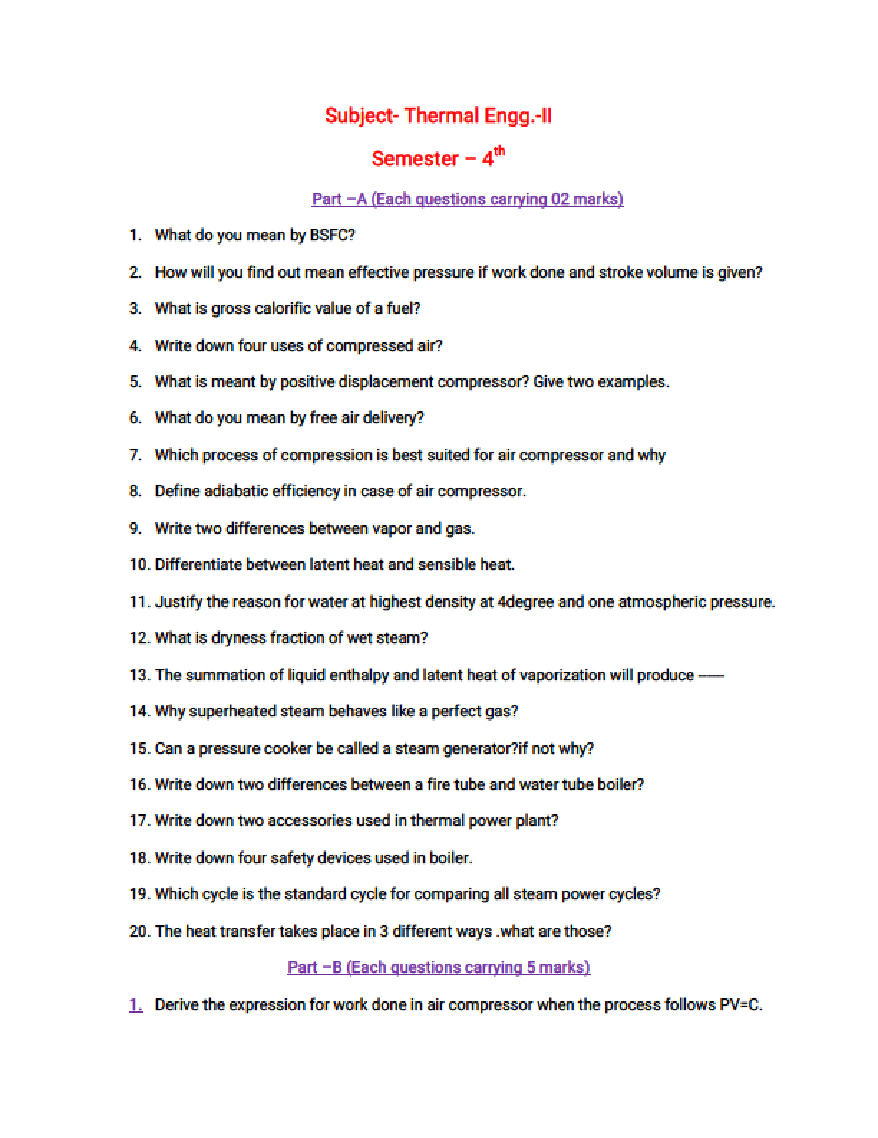

THERMAL ENGINEERING-II |

|

|

9 |

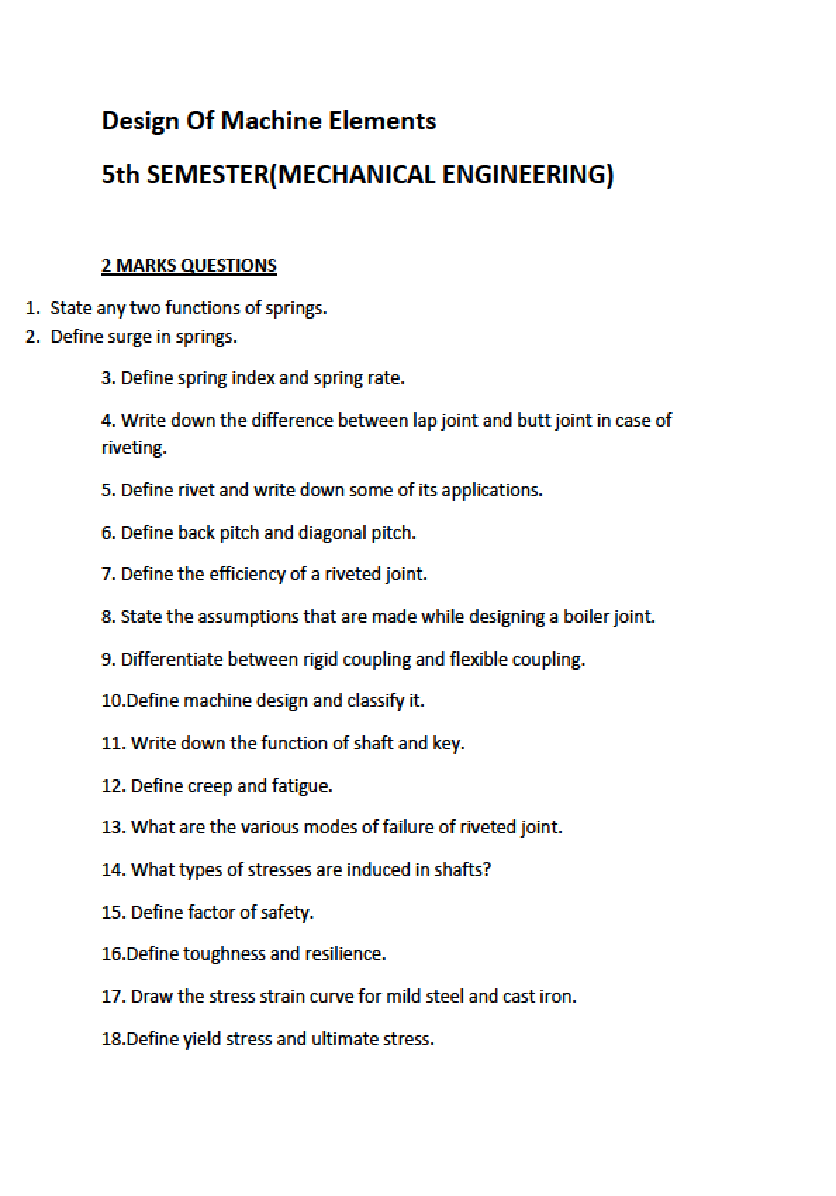

DESIGN OF MACHINE ELEMENTS |

|

|

10 |

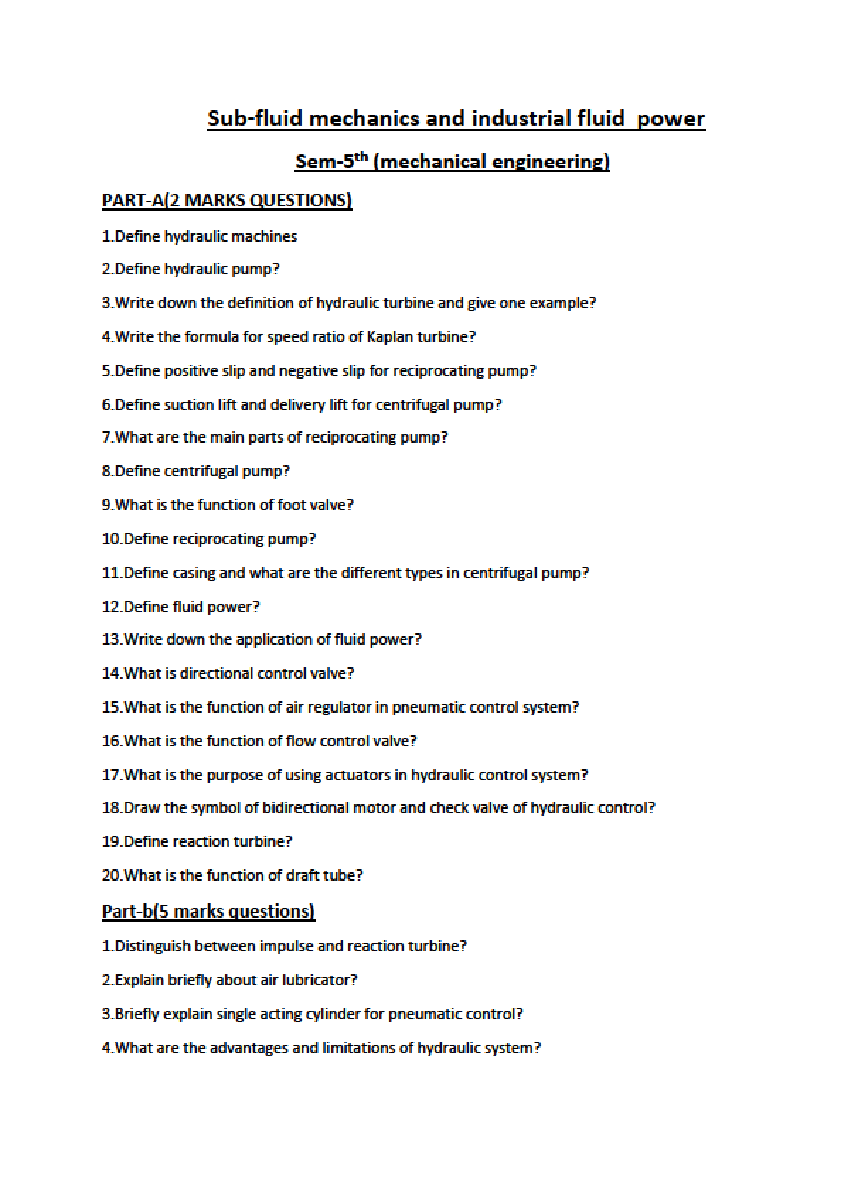

HYDRULIC MACHINE & INDUSTRIAL FLUID POWER |

|

|

11 |

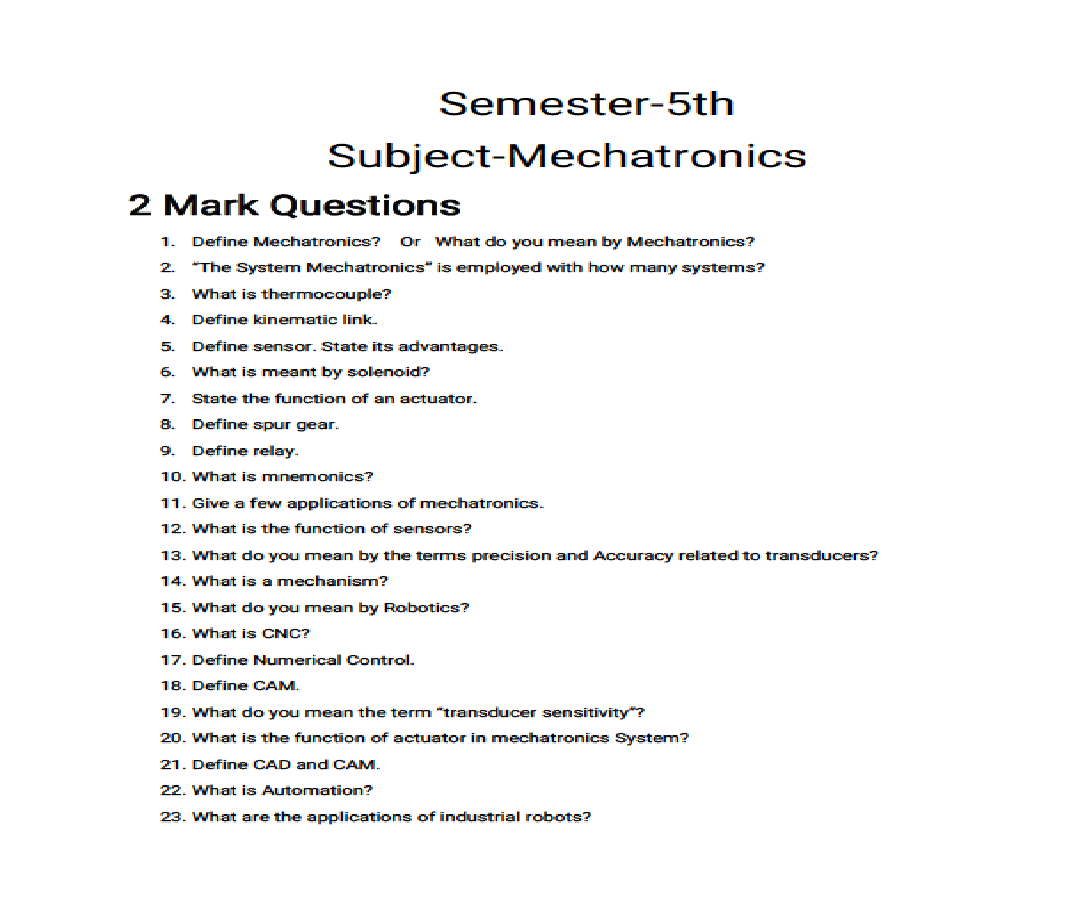

MECHATRONICS |

|

|

12 |

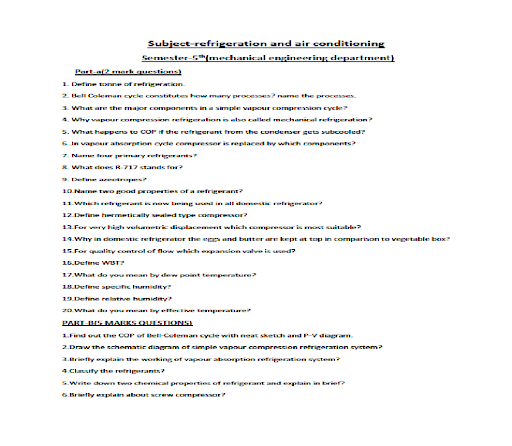

REFRIGENATION AND AIR CONDITIONING |

|

|

13 |

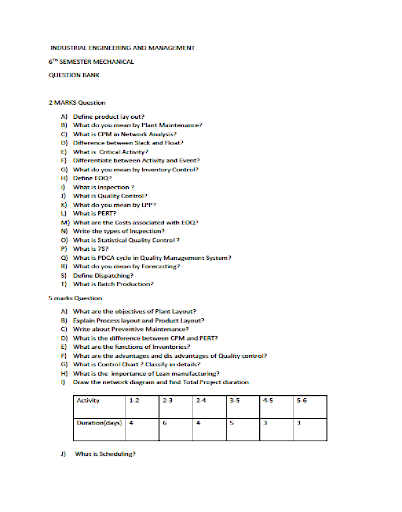

INDUSTRIAL ENGINEERING AND MANAGEMENT |

|

|

14 |

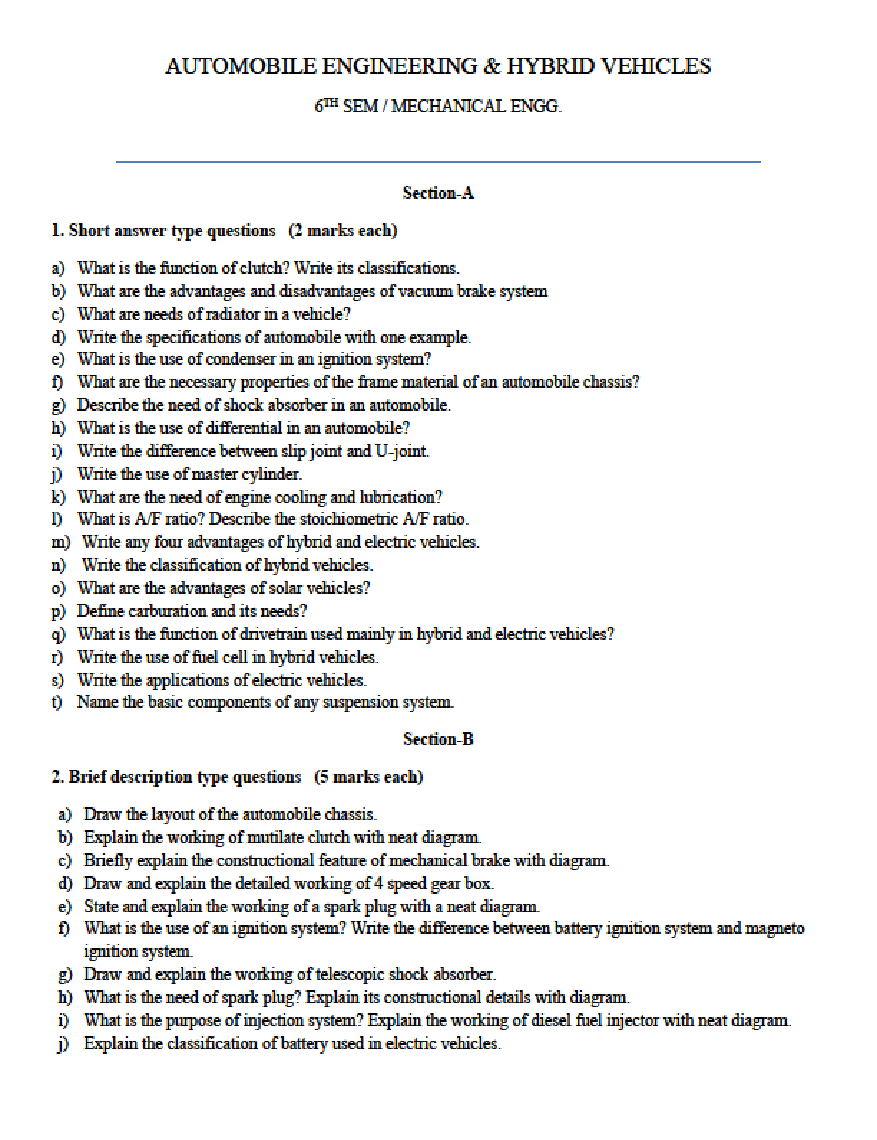

AUTOMOBILE ENGINEERING AND HYBRID VEHICLE |

|

|

15 |

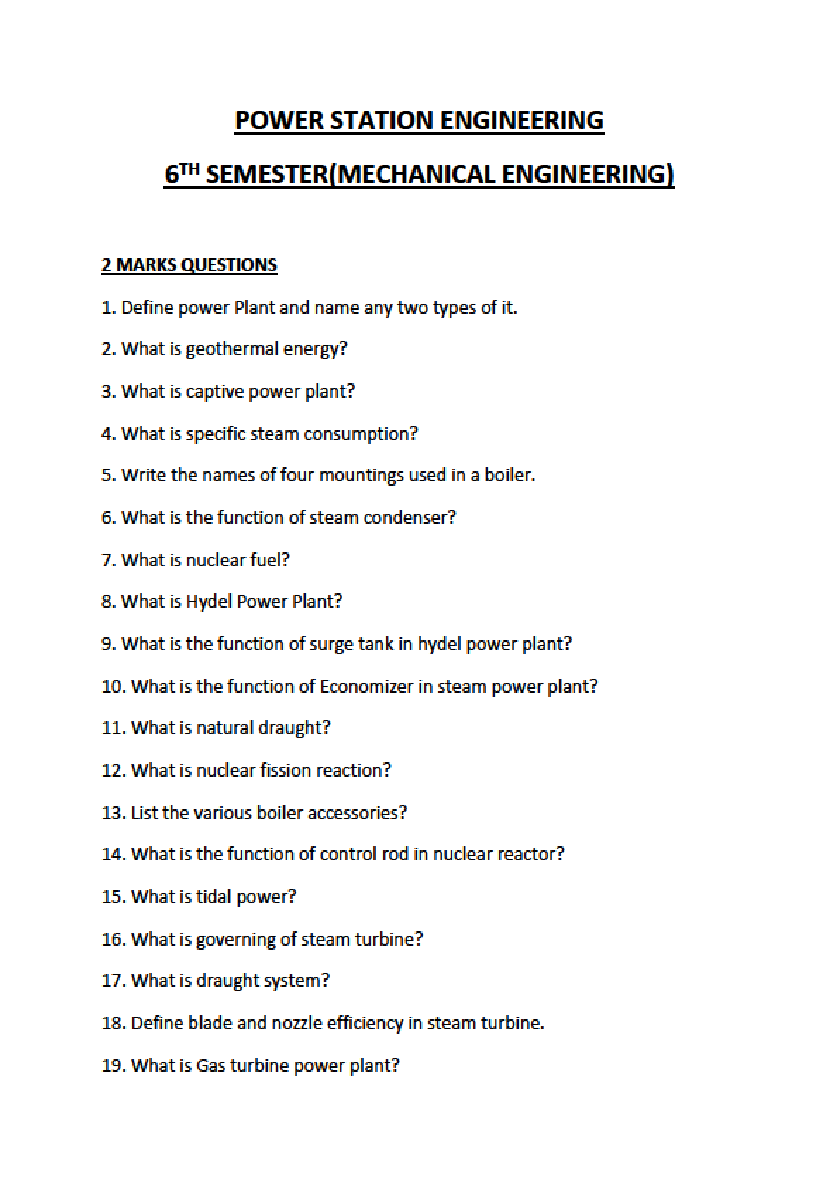

POWER STATION ENGINEERING |

|

|

16 |

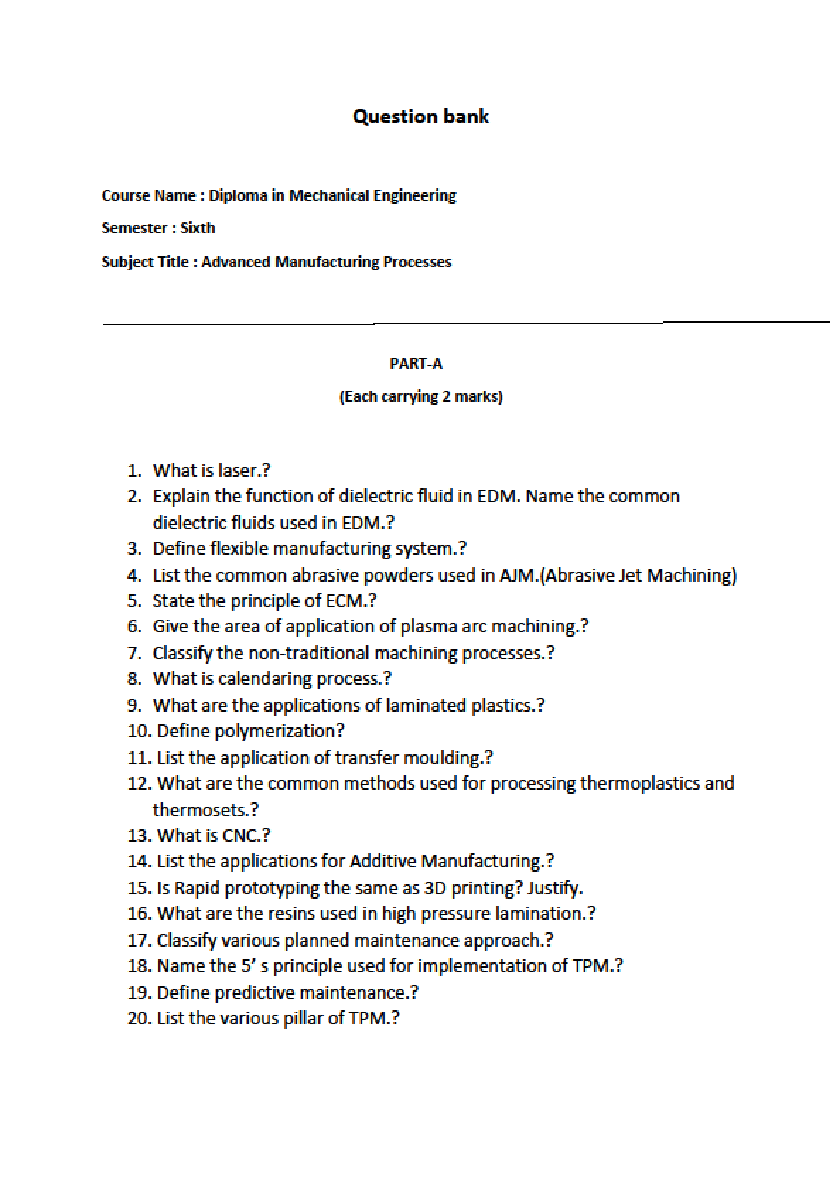

ADVANCE MANUFATURING PROCESS |

|

|

17 |

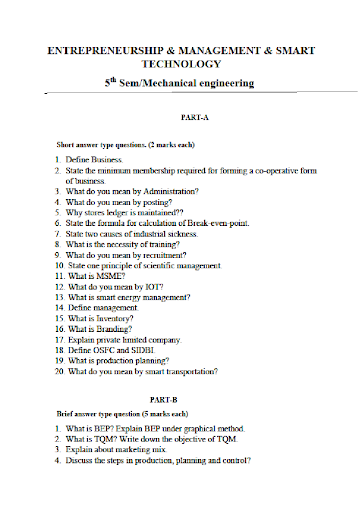

ENTERPREURSHIP MANAGEMENT AND SMART TECHNOLOGY |

|

|

18 |

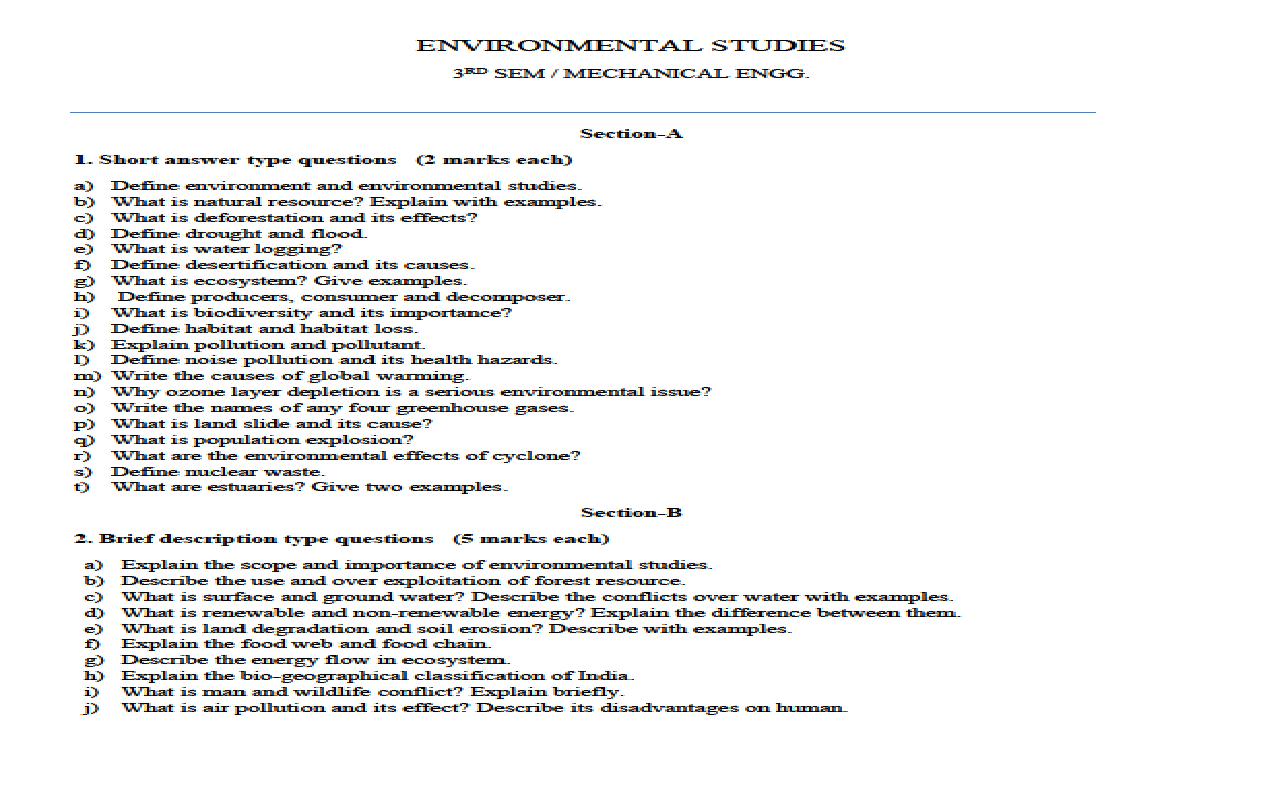

ENVIRONMENTAL STUDIES |

|

LESSON PLAN

Summer 2023

summer 2023

Subject:2nd sem ,ENGINEERING MECHANICS

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | PRASANTA KUMAR PADHI | MECHANICS |  |

| 2 | PRIYADARSHIN MALLICK | Mechanics lesson plan |  |

| 3 | BIBEKANANDA PRATIHARI | ENGG MECHANICS 2ND SEM SEC I LP. |  |

Subject:4TH SEM A,(THEORY OF MACHINE),(THERMAL ENGG-II)

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | NARESH PRADHAN | TOM TH-1 LP (4th A Summer 2022-23) |  |

| 2 | SUNITA NAYAK | lp thermal -2 4th sem |  |

| 3 | SUNITA SAMAL | Fluid Mechanics 4th sem A |  |

Subject:4TH SEM B, (THEORY OF MACHINE)(MANUFACTURING TECHONOLOGY)

Subject:6TH SEM A,AMP ,IE&M

Sem:6TH SEM B,

Winter 2022

Winter 2022

Subject:1st sem ,ENGINEERING MECHANICS

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | Prasanta Kumar Padhi | MECHANICS |  |

| 2 | Rutuparna Sahu | Mechanics lesson plan |  |

| 3 | ACHYUT KUMAR PATRA | (Engg.Mechanics) |  |

Subject:3rd SEM A,(SOM),(PT),(EVS)(TE-1)

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | NARESH PRADHAN | SOM |  |

| 2 | SUNITA NAYAK | lp thermal -1 |  |

| 3 | PRIYADARSHINI MALLIK | lp (PT) |  |

| 4 | SPBB BHATTA | (EVS)/eNV LESS cff |  |

Subject: 3RD SEM B, (Environmental Studies)(Production Technology)

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | Sunita Nayak | lesson plan PT |  |

| 2 | SPBB BHATTA | eNV LESS B |  |

| 3 | prabir kumar swain | Strength of material 3rd sem b |  |

| 4 | sushree priyadarshini | THERMAL 2 3RD SEM b |  |

Subject:5TH SEM A, Mechatronics, Design of Machine Element

| Sl. no | Name of the Faculty | Title | Download |

|---|---|---|---|

| 1 | CHIRANJEEVI PATTNAIK | mECHATRONICS AA |  |

| 2 | PRIYADARSHINI MALLICK | lesson plan MD |  |

| 3 | BIDYUT RANJAN ROUT | HMFP Lesson Plan 5th sem sec A. |  |

Sem:5TH SEM B,

LECTURE NOTE OF MECHANICAL ENGG 2021-22

|

SI No. |

Name of the Faculty |

Semester |

Subject |

Download |

|

1 |

Ms. Sunita samal |

5th |

RAC |

Chapter -3 RAC |

|

4th |

Fluid mechanics |

|||

|

2 |

Ms. Sunita Nayak |

4th |

Thermal Engg. II |

|

|

6th |

Power station Engg. |

|||

|

3 |

Ms. Sushree Priyadarshini |

6TH |

IEM 6TH SEM B |

|

|

|

|

|||

|

4 |

Mr. Prabir Kumar Swain |

2nd |

Engineering Mechanic | |

|

|

|

|||

|

5 |

Ms. Rutuparna sahu |

5th |

Design of machine elements |

|

|

|

|

|||

|

6 |

Ms. Priyadarshini Mallick |

5th |

Design of Machine Elements |

|

|

6th |

IEM |

|||

|

7 |

Mr. Bidyut Ranjan Rout |

5th |

HMIFP |

|

|

|

|

|||

|

8 |

Mr. Bibekananda Pratihari |

1st |

Mechanics |

|

|

|

|

|||

|

9 |

Mr. SPBB Bhatta |

3rd |

Environmental Studies |

|

|

4th |

Manufacturing Technology |

|||

|

10 |

Mr. Chiranjeevi Pattnaik |

5th |

Mechatronics |

|

|

6th |

Advance Manufacturing Processes |

|||

|

11 |

Mr. Prasanta kumar Padhi |

1st |

Engg. Mechanics |

|

|

|

|

|||

|

12 |

Mr. Naresh Pradhan |

3rd |

Strength of Material |

SOM CH 1 by N.K. Pradhan

|

|

4th |

Theory of Machine |

|||

|

13 |

Mr. Achyuta kumar Patra |

1st |

Engg.Mechanics |

|

|

6th |

AE&HV |

;

;

;

;

;

;

;

;